Digital twin - for whom and why? A simulation that ensures an advantage

Imagine being able to test a warehouse before it’s even built. To see where bottlenecks will occur, how much goods you can really handle per hour, and which technologies will be the best solution. To verify different scenarios and choose the one that’s most efficient. This is a digital twin – one of the most powerful tools in modern intralogistics. In this article, we explain exactly what it is and how it can support your warehouse processes.

Digital twin – what is it?

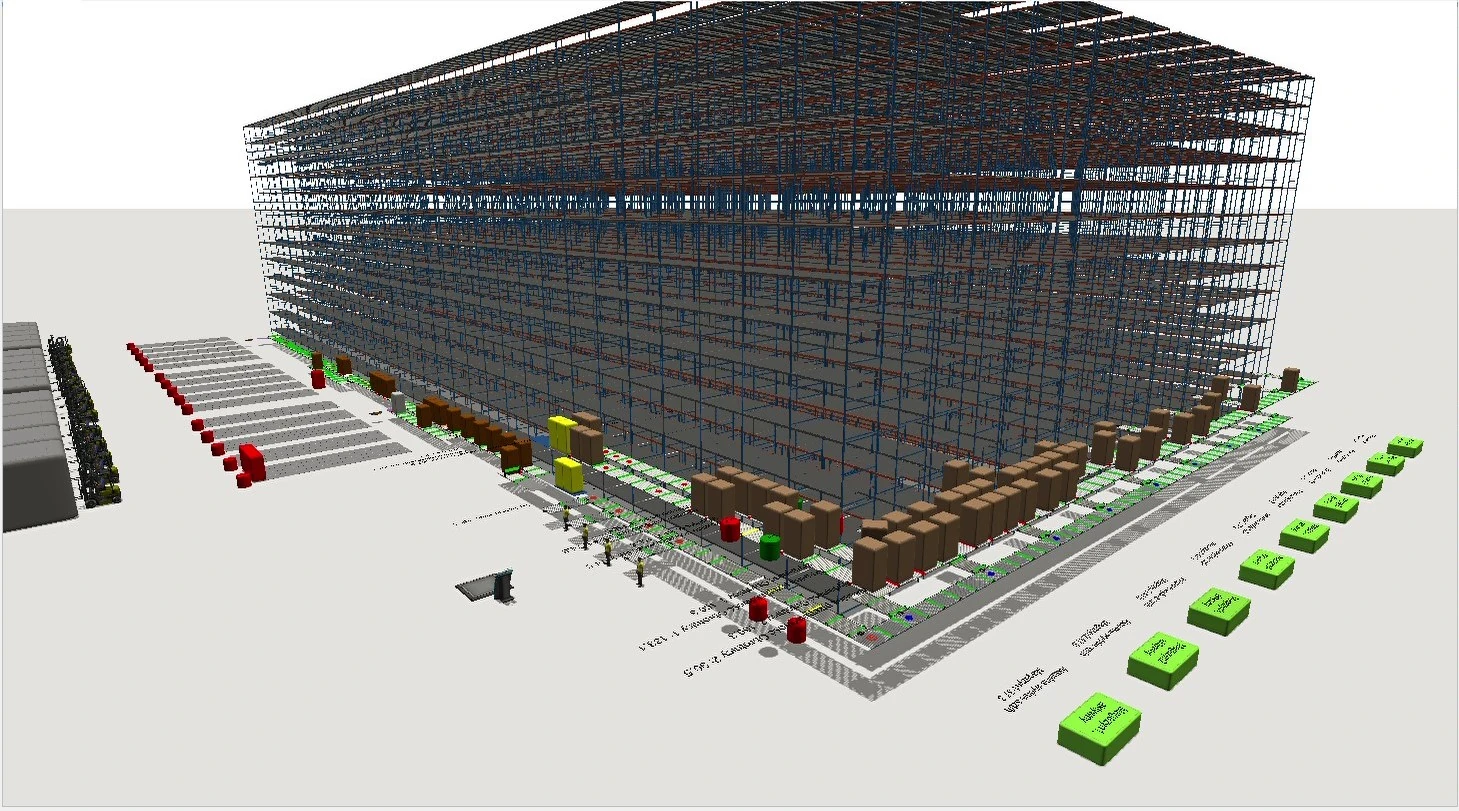

A digital twin is a dynamic, virtual model of a real system. It faithfully replicates its operation in real time or in test conditions. At MPL Techma, we put this concept into practice. We create digital twins of warehouses, conveyor lines, and integrated intralogistics systems.

Before a client commits to a particular solution, they can see how it will work, what performance it will achieve, and where bottlenecks might appear that should be eliminated. The major advantage? The client avoids the risks and costs associated with physically building the warehouse.

FlexSim – the foundation of effective simulation

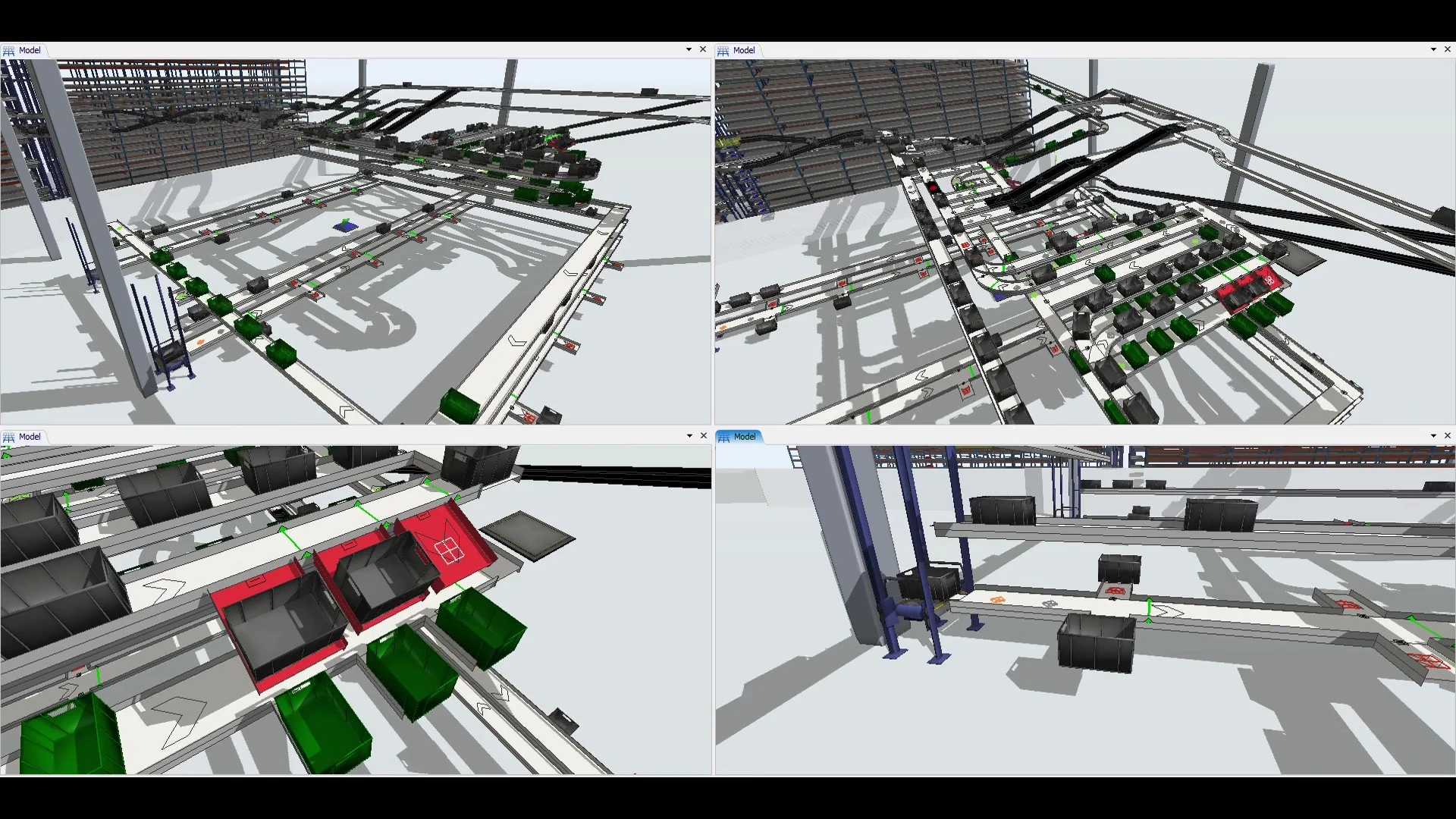

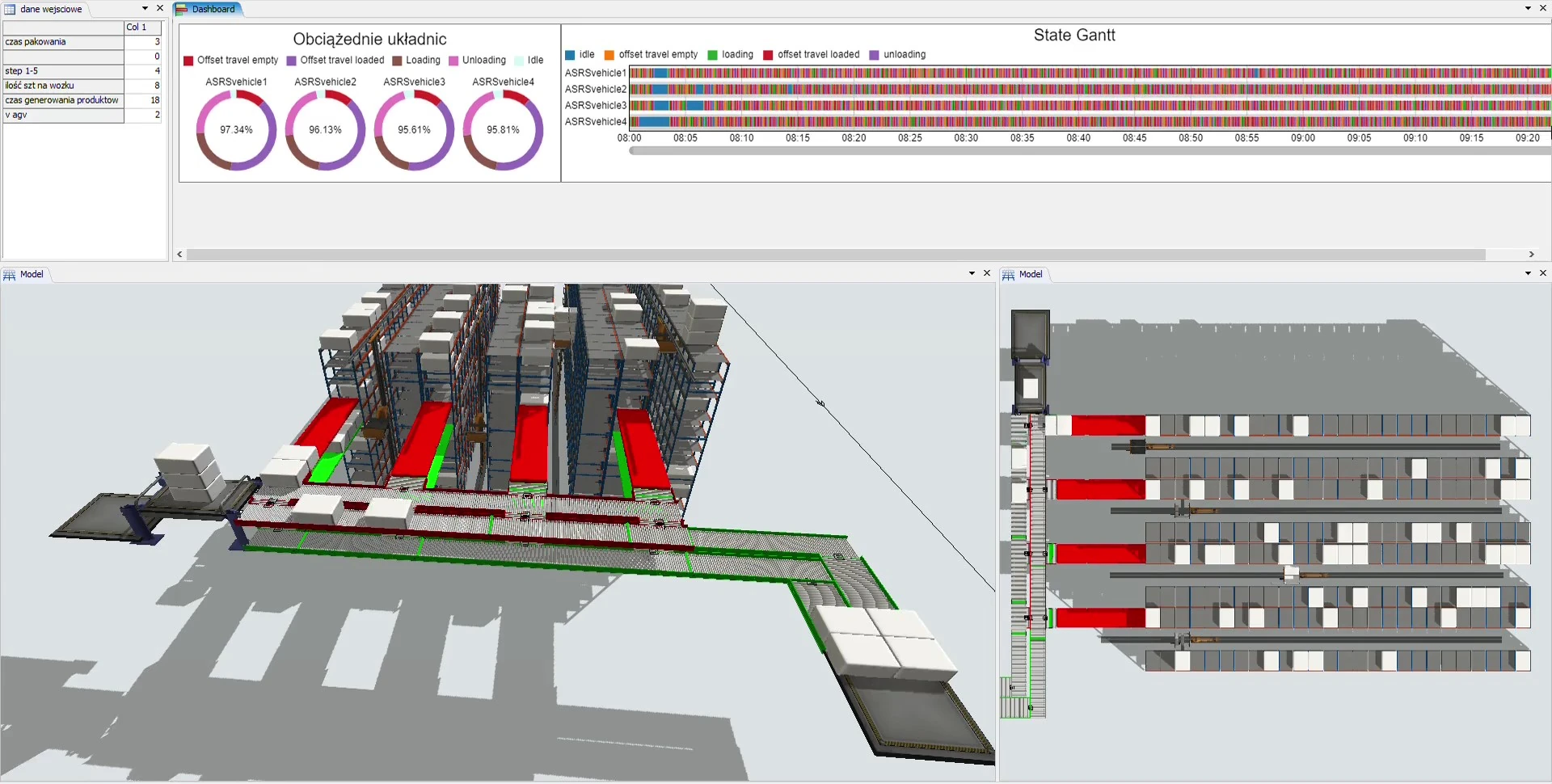

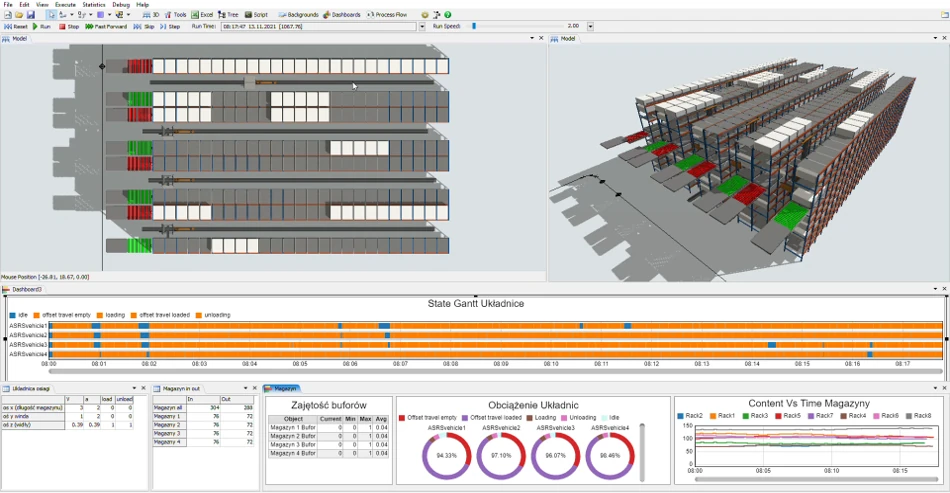

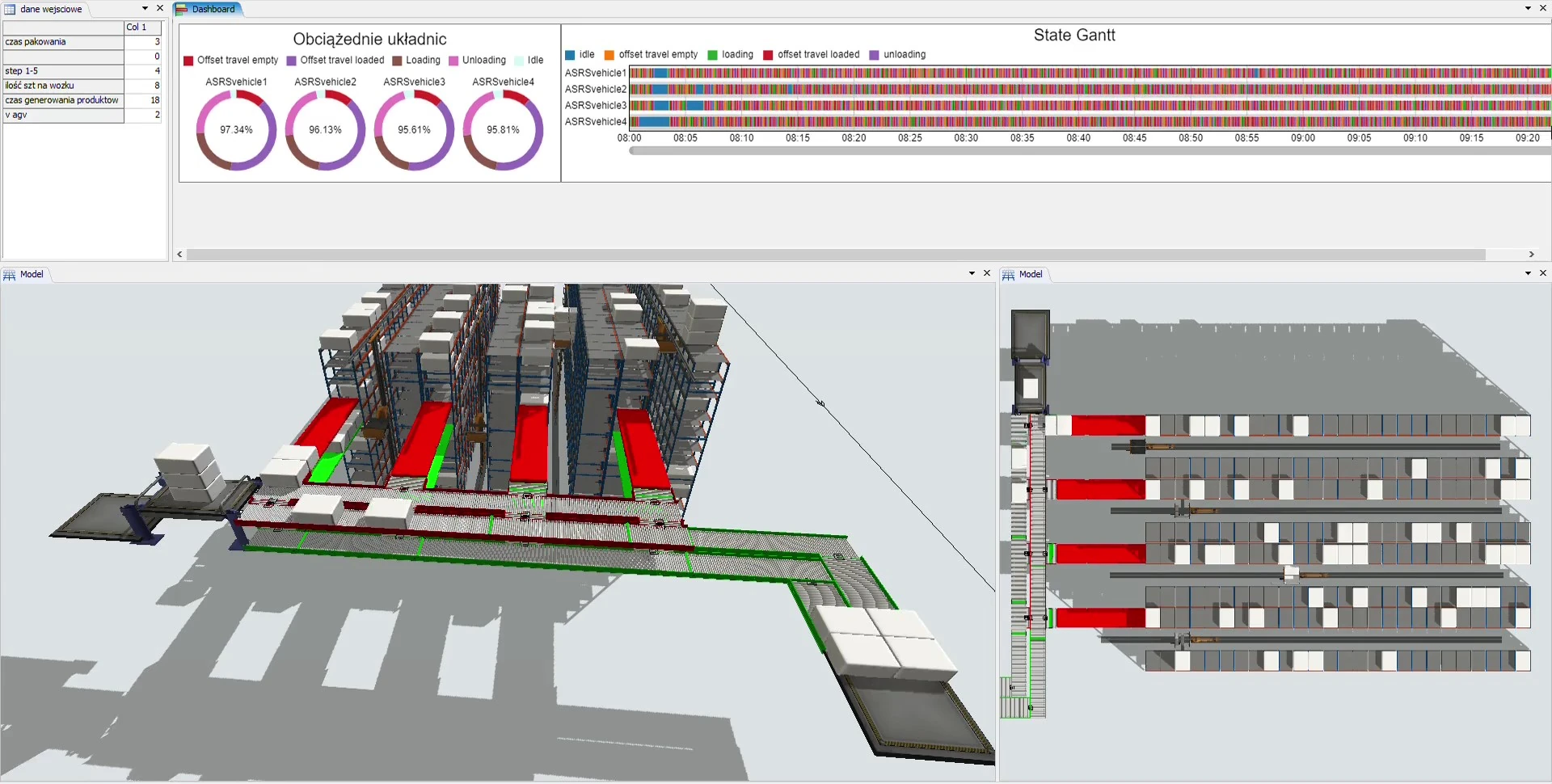

Digital twins are created using specialized software. At MPL Techma, for example, we use FlexSim, which simulates logistical and production flows. We deliver two key elements. The first is analysis, which allows us to detect bottlenecks based on actual flows in the warehouse. The second is visualization, which shows where downtime might occur and which solutions will be most effective.

We start by collecting data from the client – the number of transport units, cycle times, throughput rates, as well as spatial and technological constraints. This data becomes the foundation for building a virtual layout. Then we “bring it to life” – assigning physical properties to equipment (speeds, accelerations, reaction times) and defining the logic of system operation.

At this stage, the digital twin begins to function as a simulated warehouse. We can run tests, analyze scenarios, optimize processes, and plan the actual investment.

Who benefits from a digital twin? What does it offer?

Did you know that digital twin technology is not reserved for large companies? It benefits a wide range of businesses that:

- Plan to build a new warehouse – you can test different layout concepts before starting construction.

- Modernize existing processes – you can verify whether new equipment will fit into the current workflow and how it will affect throughput.

- Seek cost savings – to avoid unnecessary expenses and misguided investments.

How is a digital twin created?

Creating a digital twin is an iterative process – each step brings us closer to a tailor-made solution. It includes:

- Collecting input data – from actual material flows to technological constraints.

- Building the virtual warehouse model – accurately replicating the physical space, which helps with, for example, product placement.

- Defining system properties – device speeds, operating logic, collaboration rules.

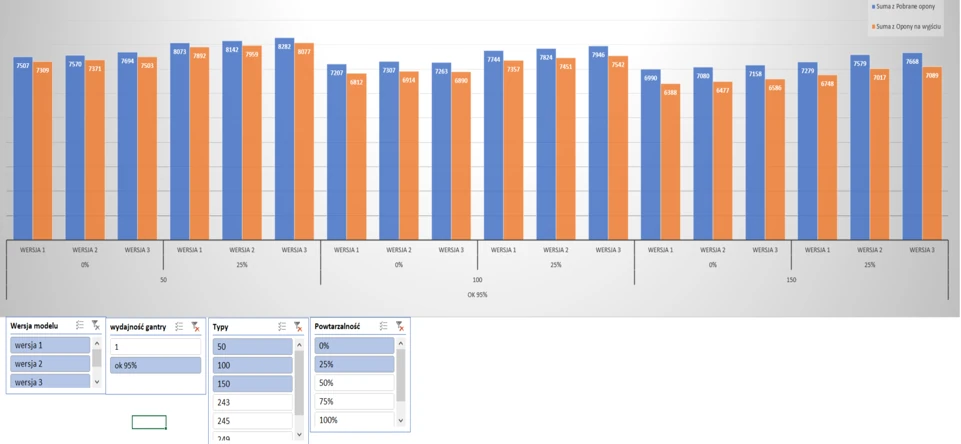

- Simulating different scenarios – from a standard workday to emergency situations.

- Analyzing results – performance, identification of bottlenecks, task completion times.

- Optimizing the solution – introducing changes that improve system performance.

- Client presentation – final visualization and analytical report.

Each iteration brings new insights and opportunities.

What will you gain with a digital twin – and is it worth it?

A food industry business owner invested millions in warehouse automation – WMS, stacker cranes, shuttle carts, conveyor systems – but skipped the digital twin stage. Although the investment initially seemed perfect… over time, bottlenecks, errors, and delays emerged. The owner didn’t fully understand the source of the problems, so he tested solutions blindly – which only made things worse.

Within a year, the company lost two major clients and over PLN 1.5 million in revenue. If they had used simulation before implementing the warehouse, they could have safely tested changes, predicted failures, and optimized processes without risk.

The investment itself wasn’t the mistake – the mistake was managing it blindly.

Of course, a digital twin is not necessary for every investment. However, its role in effective warehouse process optimization is extremely valuable.

The biggest benefit of a digital twin is certainty. The client knows that the ordered system will be tailor-made, highly efficient, and profitable. It helps avoid misguided design decisions. A digital twin also increases warehouse safety by predicting and eliminating potential hazards in advance.

The future of design begins in the virtual world

The use of digital twins is revolutionizing the automation industry. It enables modeling and real-time analysis of physical systems in a virtual environment. By integrating data from ERP, IoT, sensors, and the cloud, you can create a comprehensive digital model that can be updated and tested in different conditions.

An intelligent digital twin collects and processes data in real time. It opens the door to simulation, interaction, and predictive analytics. As a result, goods storage and other warehouse operations run more smoothly. The application of digital twins is becoming the standard in the Fourth Industrial Revolution.

At MPL Techma, we believe that modern intralogistics cannot function without digital design tools. Digital twins give us – and our clients – a real competitive advantage. It’s worth working smarter, faster, and more profitably. So, if you’re planning to build a warehouse or modernize your existing system, don’t start with costly investments. Start with a virtual model. See it before you build it. Test it before you implement it. Optimize it before you pay for it.

Contact us today!